Sweep Off

Pick & Place

De-Palletisers | Robots, Pick & Place & Sweep Off

The choice of one or the other of the technologies is made using very precise criteria associated initially with the product and its environment. Our team of project engineers are at your service to guide you and support you in this choice.

The PHS range of de palletisers are very robust and reliable and can be found in many food and beverage companies around the world. We have vast experience in de palletising many types of products, from cans to bottles to totes, bags and cased products. PHS de palletisers are designed and manufactured to the highest standards, with everything being supplied as a complete system from one source, with loose container conveying systems as required.

Pick and place technology with varying types of picking head specially adapted to the particular product are implemented, please see below for more information about our expertise in de palletising machinery.

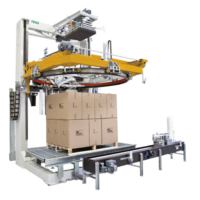

De Palletising Gantry Robots

The modular design of the PHS gantry robots are cartesian in design complete with either 2, 3 or 4 axes adapted to pallet patterns, throughputs, products and layouts.

The required space is limited only to the frame supports allowing full access and many positioning possibilities. Their working speed can reach 90 layers / hour with removal of layer sheets and empty pallets storage.

The linear movements of the machine are very reliable and precise and have the following:

- Well-adapted standard components

- Control by P.L.C.

The layer gripping arm is adapted for products to be de palletised. It can be:

- magnetic for tins or cans

- with inflatable tubes for empty bottles

- with vacuum for vials, pots, cases or bundles

- with suction cups for cartons, cases and boxes

- with peripheral clamping for crates, trays and other open containers

We can also offer additional equipment according to your needs:

- layer deposit table and product separating conveyor

- full pallet accumulation conveyors to optimize infeed flow,

- sheet pallet and empty pallet outfeed conveyors,

- exploding device (mounted on sheet gripper) for tray corners for better stacking,

- remote control panel,

- the incorporation of a cutter-crusher-disposer of attachments, strap cutter grinder and swallower,

- or other equipment upon request.

De Palletising with Articulated Robots

The Articulated de palletising robot range, provides a customized solution to every product and layout requirement:

This high-quality de palletiser, with well-proven precision, speed and flexibility, can handle complete or partial layers.

Several production lines of different products can be processed simultaneously. The gripper adapts to the product during transfer from one line to the other. Please contact PHS if you have a requirement and we will be pleased to discuss the application with you.